SOMIDA at the 29th African Day for Occupational Risk Prevention (JAPRP 2025) in Tillabéry, Niger

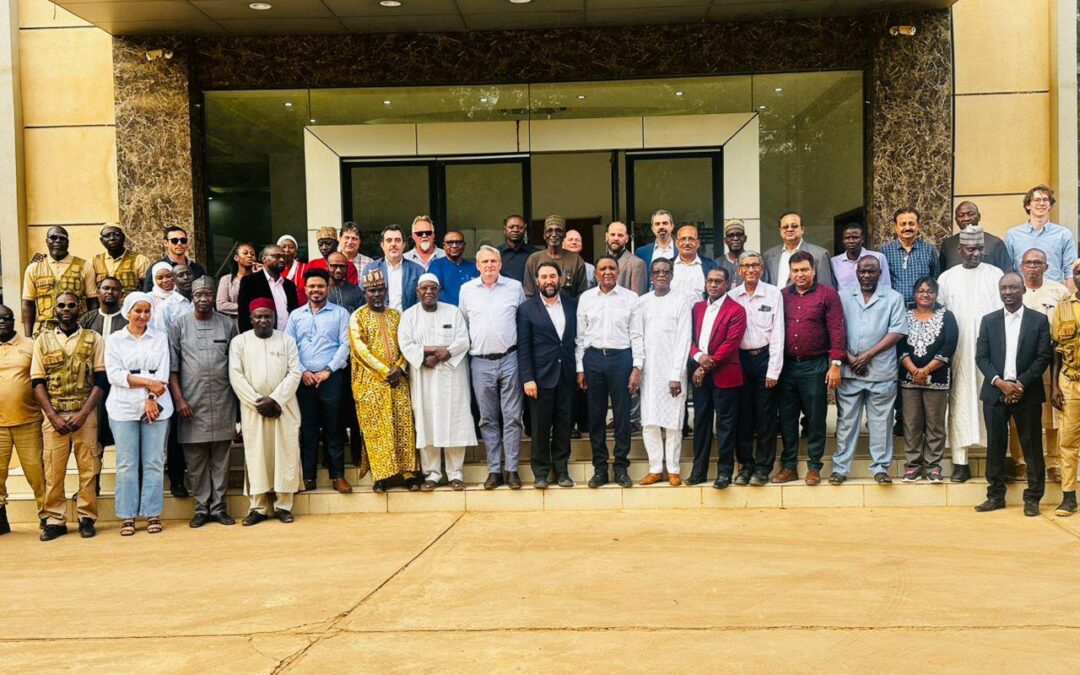

From April 25 to 26, 2025, SOMIDA took part in the workshop organized by the CNN as part of the African Day of Occupational Risk Prevention (JAPRP 2025), under the central theme: ” Occupational risk prevention in the face of digital transformation and technological change: opportunities, challenges and adaptation strategies”, with an associated sub-theme entitled “Prevention and management of food poisoning in the workplace”.

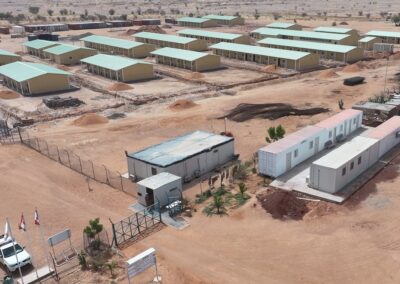

Numerous senior officials from ministries, the CNSS, public and private companies, occupational health and safety (OHS) associations, occupational medicine and university and vocational school students took part in the meeting. Société Minière de DASA, invited to this important forum, was represented by four members of its Occupational Health and Safety Committee (CSST).

Our representatives showcased exceptionally well their expertise in 3 areas:

- use of the Automatic Fire Suppression System (ANSUL)

- remote-controlled machine operation

- food poisoning prevention actions at the DASA site

The presentations on the main and secondary themes of the workshop were very well received. Participants praised SOMIDA’s new features in general, as well as best practices in workplace catering management and exemplary preventive actions.